Pumps and Tanks For Large Lawns

A large lawn will need to be watered using a pump with a tank. The reason for this is so that we can have a reliable higher pressure and a higher reliable flow. The reason for the higher flow and pressure is so that we can run more pop ups from one zone and cover the area that needs watering efficiently.

There are a lot of thing to consider prior to buying a tank and a pump and this will be covered in more detail later however here is a basic example to give you an idea.

What size tank do I need

Tanks come in many shapes and sizes and prior to buying a tank we would need to know how much water we are using and how quickly we can fill the tank while the water is being used. The example below will give you an idea of the maths used however even this can vary as many timers can have delays programmed in which will delay the start between zones in order to allow the tank to refill. In the example below we will assume we want to keep the tank as small as is possible

In this example we will have 4 zones watering the lawn. We will assume the tank is filled by the mans water supply and that it is filling at the rate of 500 litres per hour. We will assume that each zone will run for 30 minutes

Zone 1 uses 3500 litres per hour

Zone 2 uses 2500 litres per hour

Zone 3 uses 3500 litre per hour

Zone 4 uses 2500 litre per hour

Assumed information

1 The tank is filling at 500 litres per hour

2 Each zone will run for 30 minutes

If zone 1 comes on at 5 am and runs for 30 minutes it will require 1750 litres of water. In that 30 minute period we know that the tank will receive 250 litres from the main. In order for zone 1 to run completely without running out of water we would need a tank with a minimum volume of 1500 litres.

If zone 2 were to start up straight after zone 1 and our tank was only 1500 litres then it would run out of water straight away. At this point we could decide to purchase a larger tank or to programme a delay prior to starting zone 2. To fill the tank the delay would have to be 3 hours in order to completely fill the tank which would make it very awkward to water all zones at the ideal time of the day which is very early morning. Because of this we may want to increase the size of the tank in order for us to water zones 1 and 2 this morning one after the other and then zones 3 and 4 on the follow morning.

If we assume that we will water zones 1 and 2 today and then zones 3 and 4 tomorrow then the calculation for tank sizes is below

Zone 1running for 30 minutes will use 1750 litres and zone 2 will run for 30 minutes and use 1250 litres. So the total amount of water used in the 1 hour ( 30 mins per zone ) is 3000 litres. In the 1 hour period the tank fill would have supplied 500 litres so would need a tank with a minimum tank size of 2500 litres

The example above is not a true example and only supplied as a guide as there are many other point to consider prior to buying a tank for watering the lawn. Please do call or email our experts who will be happy to help or as an alternative please do use our free planning service

What Size Pump Will I need

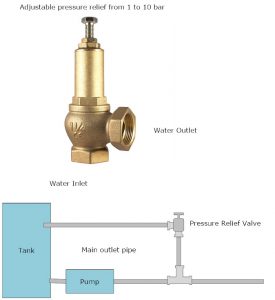

If we look at the example above we can see that both zones 1 and 3 are using 3500 litres per hour. As these have the highest volumes we will focus on these as the 2 smaller zones can if required have pressure regulators fitted. So we know we need 3500 litres per hour and we know from the previous article that we need a minimum pressure at the spray head of 1.85 bar however the ideal pressure is 2.5 bar. Something that we will not cover in detail here is friction so for this example we will assume a friction loss of .5 bar so we will need a pressure at the pump of 3 bar which will give us a pressure at the spray head of 2.5 bar.

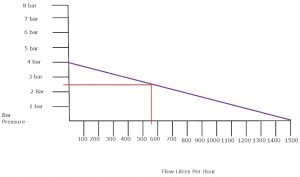

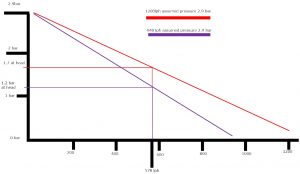

All pumps are supplied with a pump performance curve. This curve will let you know what the outlet pressure from the pump is at a given flow.

In the example above we can see 4 curves which represent various models of this particular pump supplied by the Italian pump manufacturer Dabs. The horizontal line along the bottom shows the flow and the vertical line at the side shows pressure. If we put a mark at the 3500 litre per hour mark and draw a straight line up we can see that the smallest model would be totally unsuitable for our application. However if we follow the red line across we can see that two models fit our requirements and will deliver 3.5 bar at the pump or if we look at the purple line we can see that the larger pump in this family will deliver 4.5 bar when running with a flow of 3500 litres per hour

In this article we have not covered friction related to pipe sizes, fittings, filters, valves etc. Soe of these will be to complex on very large systems so please do take advantage of our free planning service